Categories

B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

key word::

B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

Category:

- Details

-

1.Application of B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

Used in the sedimentation tank of water purification plant to remove the sludge that settles at the bottom of the tank. According to the type of sedimentation tank, it can be divided into two categories

- Advective sedimentation tank suction machine

- Inclined tube sedimentation tank suction mud machine

2.Features of B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

1. Adopt German technology - submersible non-clogging pump sucking mud, can run at full head, good performance, light weight, overcome the defects of wear and installation and maintenance difficulties caused by vibration caused by the shaft length of the submerged pump in the past.

2. Using our company's unique small-capacity submersible sewage pump, a suction system with only one suction nozzle for each pump can be realized, so that even if there is a water supply process layout with a longitudinal water outlet and its buttress at the outlet end of the sedimentation tank, the suction machine is still unobstructed, ensuring mud removal over the entire length.

3.The dual-purpose of pump/siphon makes water saving and energy saving. In the sedimentation tank with siphon sludge discharge conditions, the potential difference between the water outlet weir and the sludge discharge port can be fully utilized. After the submersible sewage pump starts to discharge the sludge, the power supply of the submersible sewage pump is cut off, and the pump suction is converted into a siphon, which saves both water and energy without system evacuation.

4. Since no vacuum device is required, the operation is simple and easy to realize automation and computer management.

5. The main beam structure is reasonable, it adopts single or double tubular beam, section steel beam. In particular, the water suction and conveying pipe in the inclined tube sedimentation tank is both a channel and a bearing member, so the material is saved and the manufacturing and maintenance are convenient.

6. Optional new type of transmission, the key components in the drive - adopt the new product shaft-mounted or flange-mounted reducer, no coupling, no need for centering, compact structure, high efficiency, light weight.

3.Construction and working process of B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

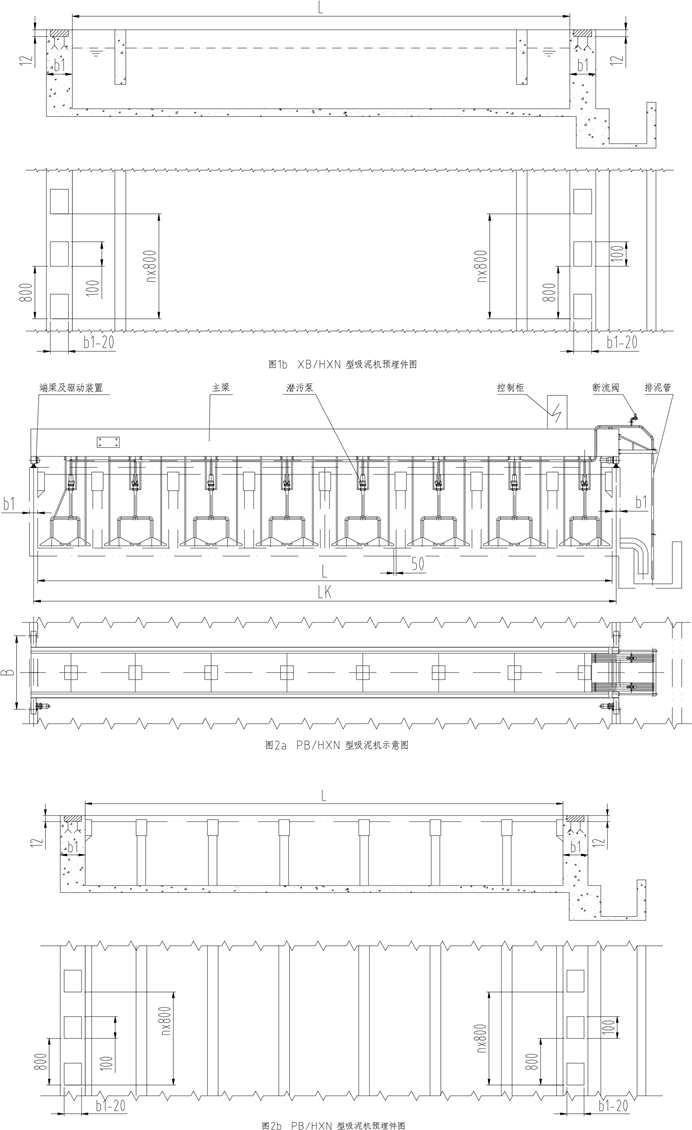

As shown in Figure 1~2, it consists of multiple submersible non-clogging pumps to form suction, mud conveying system, shut-off valve, main beam, end beam and driving device, track and control cabinet.

The main beam is driven by the driving devices on the beams at both ends, and travels along the track laid on the top of the pool. The submersible sewage pump moving with the main beam absorbs the sludge deposited at the bottom of the pool and discharges it to the outside of the pool through the mud conveying pipe-mud ditch. When the sedimentation tank with siphon condition (the difference between the outlet weir of the sedimentation tank and the sludge discharge port is not less than 3 meters), the power supply is cut off after the submersible sewage pump starts to discharge the sludge, and the sludge discharge method can be switched from pump suction to siphon; when it is required to stop the sludge discharge, the shut-off valve can be opened, and a large amount of air will enter the sludge pipeline, the siphon will be destroyed, and the sludge discharge will be interrupted immediately.

4.Product Specifications of B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

PB/HXN-12

PB/HXN-14

PB/HXN-16

PB/HXN-18

model

XB/HXN-12

XB/HXN-14

XB/HXN-16

XB/HXN-18

PB/HXN-20

PB/HXN-22

PB/HXN-24

PB/HXN-26

pool width L (m)

12

14

16

18

20

22

24

26

Span LK(m)

Determined according to process requirements

Wheelbase B (m)

~LK/(6~8)

Speed m/min

1~1.5

Power KW

2x0.37

Matching submersible sewage feature

P=1.4kW,Q=54m3/h,H=2m

P=0.4kW,Q=15m3/h,H=1.5m

Number of pumps and layout of suction ports

Determined according to process requirements

Pool depth m

<= 4m

Rail model

22Kg/m GB11264-89

30Kg/m GB11264-89

Dimensions of rail embedded parts(mm)

(pool wall thickness -20)x60x10

轨道预埋件间距(mm)

600

maximum wheel pressure KN

15/13

20/16

25/20

30/25

35

40

45

50

5.Structure diagram of B/HXN Feedwater Settling Tank Pump/ siphon suction dredge

Related products

Product inquiry

Contact Information

No. 192, East Bianzhong Road, Chengqiao Street, Liuhe District, Nanjing