Categories

QJB650-A150/12 submersible mixer

key word::

QJB650-A150/12 submersible mixer

Category:

- Details

-

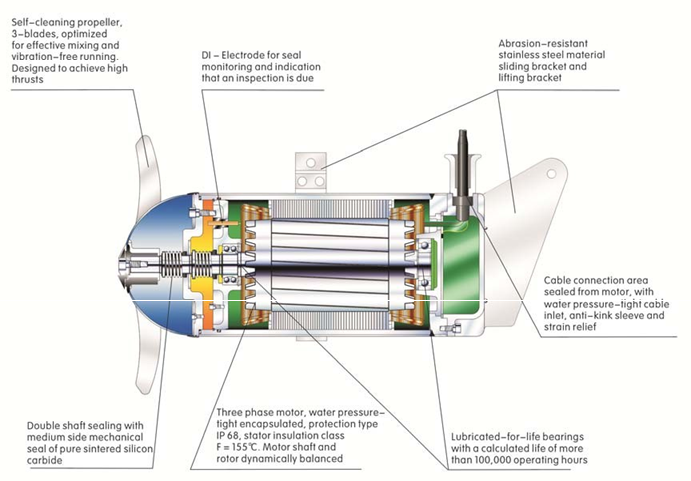

The QJB submersible mixer have been designed for a wide range of applications. The units can, for example, be used for many mixing and stirring applications in sewage treatment plants and in industrial and chemical processes.

The submersible mixers can be installed in all tank shapes and sizes. Depending on the requested intensity of mixing and flow formation, one or more mixers may be installed in a single tank.

Features:

Name Description

Motor

IP68, F class insulation, 50 or 60 Hz, three phase Thermal sensor for each phase

Propeller

Technically optimized, axially operating 3-blade propellers with very good self-cleaning effect for vibration-free operation.

The propellers are designed to achieve high thrusts and therefore a high flow capacity in axial direction

Mechanical seal

Double highly quality sealing unit using a SiC/SiC, independent of direction of rotation and resistant to temperature shock.

Bearing

All bearings are lubricated-for-life and maintenance-free, with a calculated life time of more than 100,000 hr.

Shaft

Strictly static and dynamic balance check to ensure the smooth operation

Cable

10 m sewage resistant CSM material. Type: H07RN.

Protection

With DI sensor located in oil chamber, it will detect any moisture before enter into the motor chamber from the shaft seal. And give you timely warning about the problem occurred.

Materials:

Specification Material

Motor casing

SS304 ( SS316 for optional)

Shaft

SS420

Propeller

SS304 ( SS316 for optional)

Mechanical seal

WuC / SiC or SiC / SiC

Sliding bracket

SS304 ( SS316 for optional)

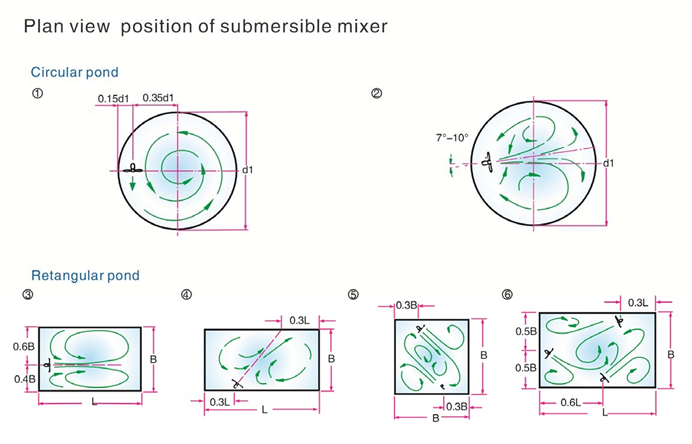

Submersible mixer must be installed like above position for different shape of pond.

Submersible selection

Power consumption P ≧ V(m3) * C (w/m3) * k1 * k2 * k3

V --- Volume of water to be treated

C --- Power consumption per m3 clean water, generally 4.8w/m3

K1 --- Correction factor of medium density, generally 1.1~1.15

K2 --- Correction factor of pond shape, generally 1.06~1.1

K3--- Service factor, generally 1.2

Final formula: Mixer power P (w) ≧V (m3) * 6.8 (w/m3)

Mixer model selection and calculation paper

Installation:

The mixer should be installed as deep as possible.

- If in one tank, 2 or more mixer installed, in order to have good stirring performance, each mix flow should be continuous to connect to others, and will not interaction each other.

- Distance between floor and blade's top edge should be more than 400mm,like below figure, HMIN>400mm. If lower than Hmin, the mix flow will hit the floor, and not stir the water, waste the energy.

- Distance between water level and blade's top edge should be minimum 1.5 times of blade diameter. Like below figure, HABOVE>1.5 times D ( impeller diameter) , If lower than Habove, the mix flow will hit above the water level, also waste the energy.

- Distance between wall and top blade should be at least 2 times of impeller diameter. Lmin > 2 times D ( impeller diameter) If lower than this distance, there maybe vibration, and easy damage the mixer.

Technical data:( On the basis of 380v / 50Hz/3ph)

Rated Power : 15 / 11 HP/kW

Rated current: 32 A

Propeller Dia. : 615 mm

Speed : 480 rpm

Wt. : 229 kg

Related products

Product inquiry

Contact Information

No. 192, East Bianzhong Road, Chengqiao Street, Liuhe District, Nanjing