Categories

WLS Shaftless Screw Conveyor

key word::

WLS Shaftless Screw Conveyor

Category:

- Details

-

1.Application of WLS Shaftless Screw Conveyor

It is used for conveying fine grid decontamination machine grid slag and sludge cake after sludge dewatering in sewage treatment plant.

2.Construction and delivery process of WLS Shaftless Screw Conveyor

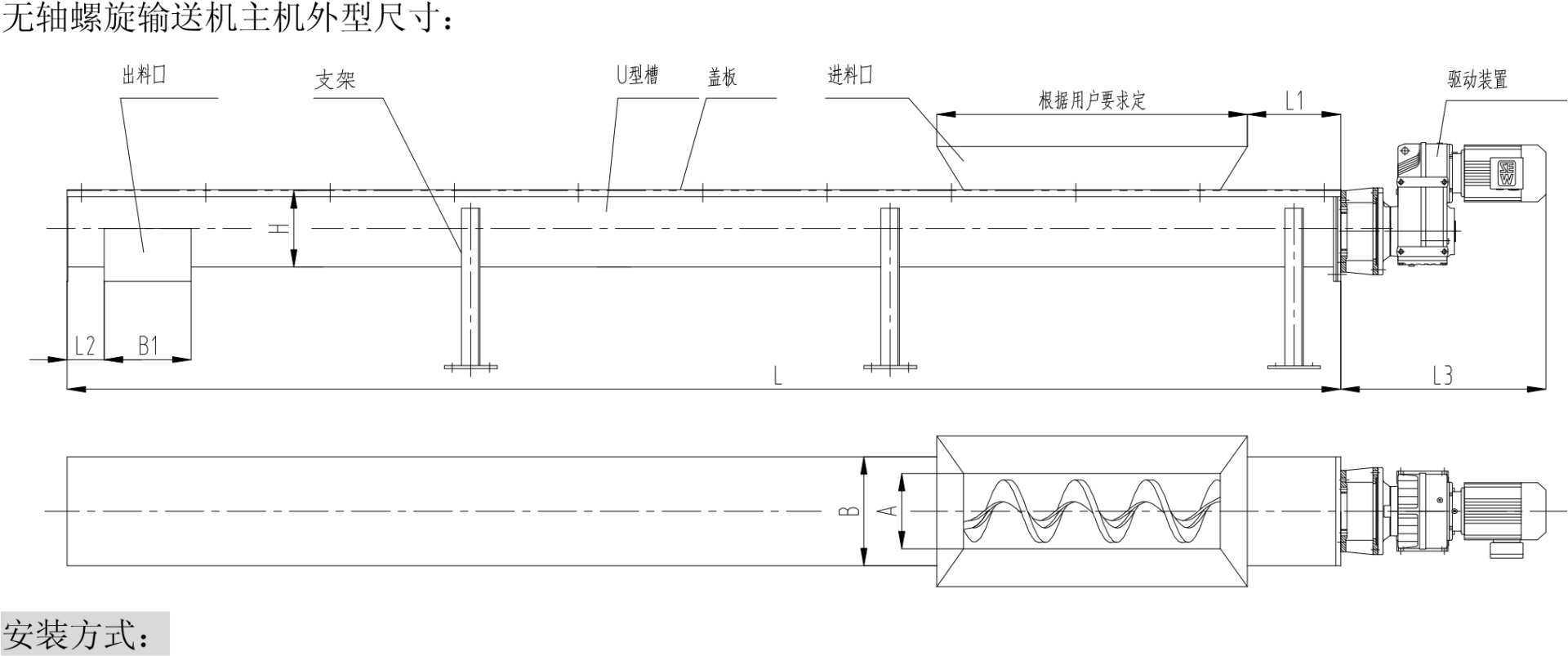

WLS type shaftless screw conveyor consists of shaftless screw, U-shaped groove, lining plate, cover plate, inlet and outlet and driving device.

The material is input from the feed port, and is output from the discharge port after being pushed by the screw.

3.Features of WLS Shaftless Screw Conveyor

1. Simple structure, no bearing in the chute, smooth material conveying and easy maintenance.

2. Except for the opening of the inlet and outlet, the rest of the parts can be covered and closed, so that the material will not overflow and reduce air pollution.

3. Easy to install, just use expansion bolts to fix.

4.Product Specifications of WLS Shaftless Screw Conveyor

model

Reference delivery volume m3/h

size mm

Conveying length

installation angle

A

B

H

L1

L2

L3

B1

WLS260-N

2.5

1.8

1.4

260

360

270

150

≦70

≦20

≦30

WLS300-N

5

4

2.2

300

400

310

200

≦70

≦30

WLS320-N

6

4.5

3

320

420

330

200

≦70

WLS355-N

8.5

6.2

4.5

355

460

370

250

≦70

WLS400-N

10.5

8.5

6

400

500

410

250

≦70

WLS420-N

12

9.5

7

420

520

430

250

≦70

WLS500-N

15

12

9

500

600

510

250

≦70

WLS260-Z

4

2.8

1.8

260

360

270

150

≦70

≦20

WLS300-Z

7.5

5.5

4.5

300

400

310

200

≦70

WLS320-Z

10.6

7.4

5.6

320

430

330

200

≦70

WLS355-Z

12.6

8.9

6.4

355

460

370

250

≦70

≦30

WLS400-Z

15.2

11.5

6.5

400

500

410

250

≦70

WLS420-Z

16.8

12.3

7.6

420

520

430

250

≦70

WLS500-Z

21.5

17.5

10.5

500

600

510

250

≦70

5.Structure diagram of WLS Shaftless Screw Conveyor

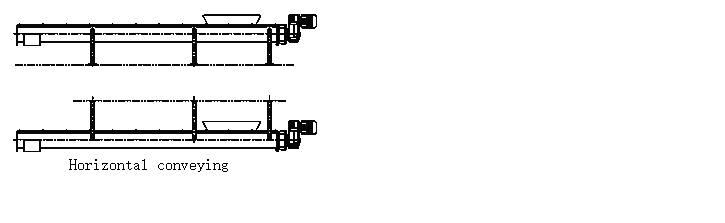

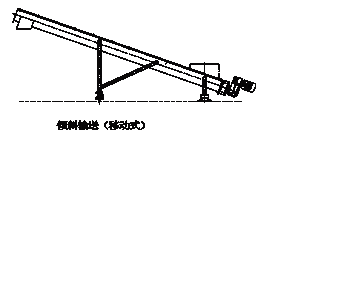

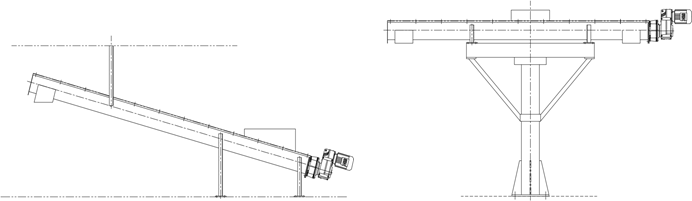

6.Installation diagram of WLS Shaftless Screw Conveyor

Related products

Product inquiry

Contact Information

No. 192, East Bianzhong Road, Chengqiao Street, Liuhe District, Nanjing