Categories

ZBXN Peripheral Drive Half-bridge Suction Dredger

key word::

ZBXN Peripheral Drive Half-bridge Suction Dredger

Category:

- Details

-

1.Application of ZBXN Peripheral Drive Half-bridge Suction Dredger

It is used in the circular secondary sedimentation tank of the sewage treatment plant to scrape the sludge settled at the bottom of the tank to a group of suction pipe nozzles arranged along the radius, and then discharge it through the central sludge discharge pipe for sludge return or concentration and dehydration. At the same time, the scum on the pool surface is skimmed to the slag collecting hopper, and discharged out of the pool through the slag collecting hopper for further treatment.

2.Features of ZBXN Peripheral Drive Half-bridge Suction Dredger

1. Simple structure and light weight: due to the use of half-bridge type, there is only one set of driving devices, and the main girder is also used as a mud trough. Compared with the full-bridge dredger that is widely used in China, the weight is significantly reduced.

2. Save operating costs, easy maintenance and management

3. A new type of transmission device can be selected, and the key component in the drive device—the reducer adopts advanced shaft-mounted type, no need for centering, no coupling, compact structure, high efficiency and light weight

4. It can be equipped with an over-torque protection mechanism. When the torque reaches the set value, it will automatically alarm and stop, which is safe and reliable.

3.Construction and working process of ZBXN Peripheral Drive Half-bridge Suction Dredger

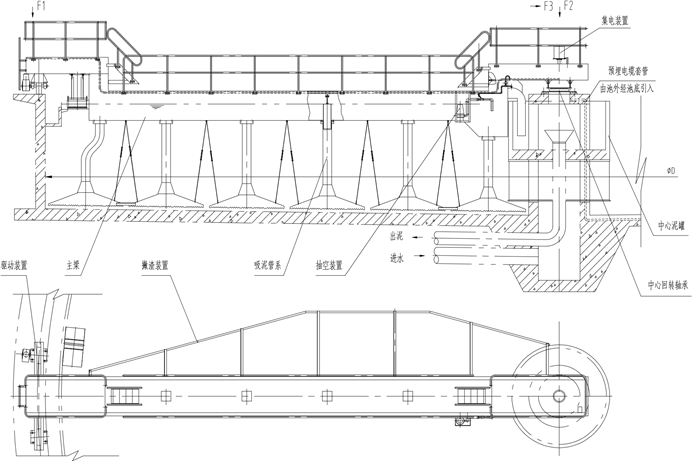

As shown in Figure 1, the ZBXN series dredger is a peripheral drive siphon type. It consists of a main beam that doubles as a mud trough, a suction pipe system, a siphon evacuation system, a central mud tank, a central rotary bearing, a driving device, a slag skimming device, Collector, control cabinet, etc.

The main beam is driven by the driving device placed on the periphery and rotates around the central axis of the pool. The sludge deposited on the bottom of the pool is scraped and collected by the scraper to each suction port. Under the action of the liquid level difference, the sludge passes through the suction port, mud tank, siphon, central mud tank and central mud discharge pipe are discharged to the sludge pit. The upper end of each suction pipe is provided with a regulator to adjust the flow distribution of each suction pipe. At the same time, the scum on the liquid surface is concentrated in the tapered area formed by the skimmer plate rotating with the main beam and the peripheral scum baffle plate, until its closed edge - the slag scraping swing arm. When the swing arm reaches the slag collecting hopper, the slag scraper on the swing arm will scrape it to the slag collecting hopper.

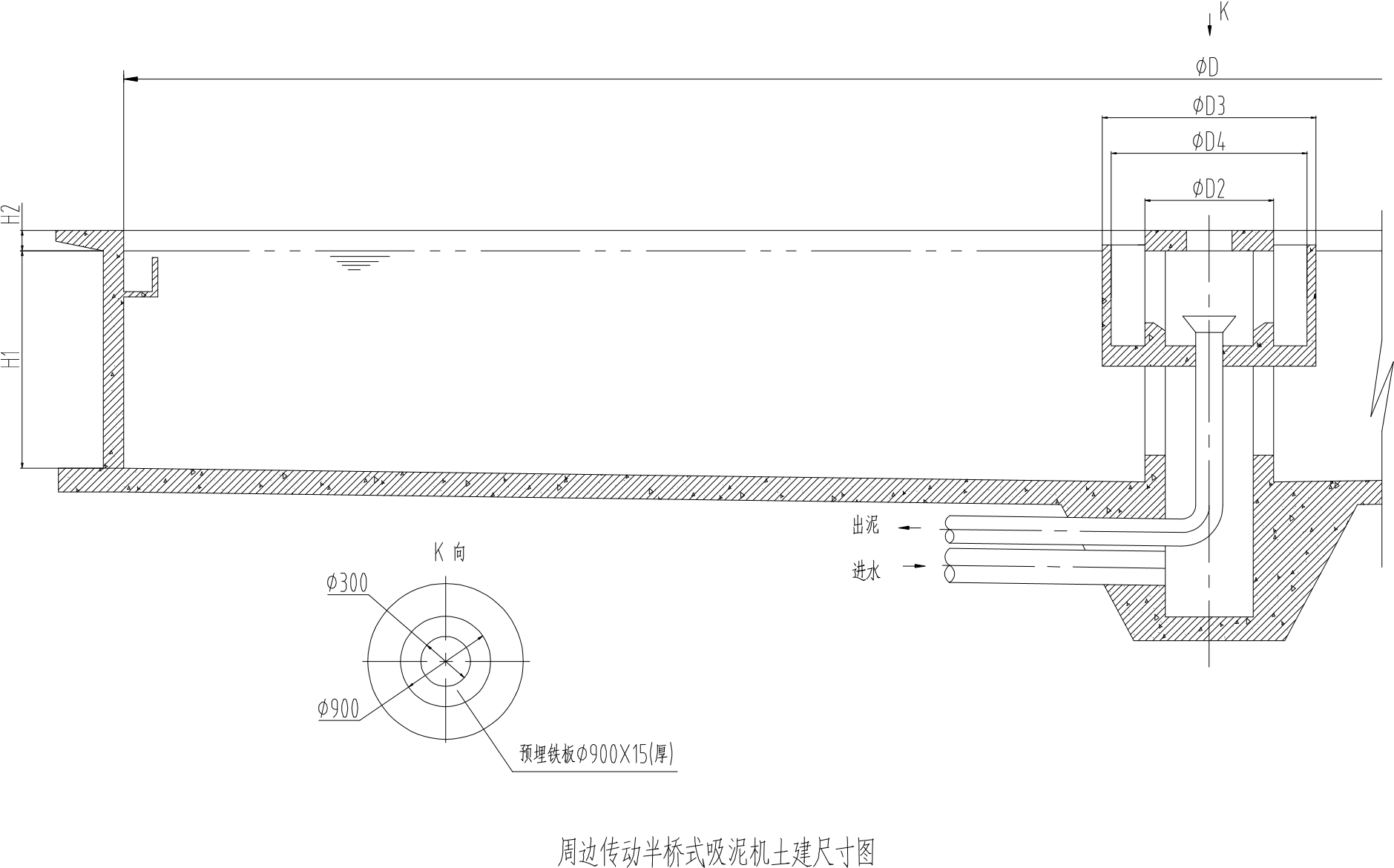

4.Product Specifications of ZBXN Peripheral Drive Half-bridge Suction Dredger

Pool diameter D m

18

20

22

24

26

28

30

32

34

36

38

40

Center tube diameterD2

1250

1550

1990

2100

D3 mm

2300

2000

2950

3150

D4 mm

2100

2400

2750

2950

Pool side depth H1 m

2.4

2.6

2.8

3.1

Pool top extra high H2 m

0.45

0.55

Sludge pipe diameter m

0.4

0.5

0.6

0.7

Rolling surface load 2xF1 kN

2x6

2x14

2x20

2x28

Center barrel load F2 kN

16

22

33

44

Center tube radial load F3 kN

6

11

17

28

Raceway width L m

0.45

0.5

0.55

Peripheral line speed m/min

<=1.8

Drive motor power kW

0.37

Vacuum system motor power kW

3

5.Structure diagram of ZBXN Peripheral Drive Half-bridge Suction Dredger

Related products

Product inquiry

Contact Information

No. 192, East Bianzhong Road, Chengqiao Street, Liuhe District, Nanjing