Categories

Floating pontoon propeller

key word::

Floating pontoon propeller

Category:

- 产品描述

-

The submersible low-speed streamer is a type of submersible mixer with a lower rotational speed, mainly composed of a submersible motor, a reduction device, blades, and an installation system. The motor drives the rotation of the front impeller through the reduction device, creating stirring and disturbance in the surrounding water while causing the water to circulate forward, thus achieving no sedimentation of the liquid and increasing the oxygen absorption of the liquid.

The low-speed streamer is suitable for aeration tanks and anaerobic tanks in industrial and municipal wastewater treatment plants. It generates a strong water flow with low tangential flow, and the low-speed streamer can be used for water circulation in the tank and to create water flow during nitrification, denitrification, and phosphorus removal stages.

I. Performance Characteristics

1. Compact structure, small size, lightweight, simple operation and maintenance, convenient and quick installation, and long service life.

2. The blades have a self-cleaning function, preventing debris from entangling and clogging.

3. When used in conjunction with the aeration system, it can significantly reduce energy consumption, increase oxygenation, and effectively prevent sedimentation.

4. The motor winding is F-class insulated, using maintenance-free imported bearings with one-time lubrication, equipped with oil chamber leakage detection and motor winding overheating protection functions, making the motor's operation safer and more reliable.

5. The friction pair material of the mechanical seal is corrosion-resistant tungsten carbide, and all fasteners are made of stainless steel.

II. Product Applications:

Streamers are generally used for stream propulsion in oxidation ditches of wastewater treatment plants, stirring in various biochemical tanks, preventing freezing in rivers, circulating landscape water, as well as in aeration tanks and anaerobic tanks of industrial and municipal wastewater treatment plants. The impeller generates a strong water flow with low tangential flow, which can be used for water circulation in the tank and to create water flow during nitrification, denitrification, and phosphorus removal stages, as well as to open river channels and prevent freezing of riverbeds.

The low-speed submersible streamer is made of elastic polyurethane or aluminum alloy, capable of withstanding varying loads, with thrust evenly distributed over the mixture. It features two reliable mechanical seals with no leakage, and is equipped with protection functions for leakage and overheating. It is easy and quick to install, suitable for various types of tanks.

Product Introduction

The submersible mixer, also known as a submersible propeller, is suitable for the process flow in wastewater treatment plants to propel and stir wastewater containing suspended solids, dilute slurries, industrial process liquids, etc., creating water flow, enhancing stirring function, and preventing sludge sedimentation. It is an important piece of equipment in municipal and industrial wastewater treatment processes: divided into mixed submersible mixers and submersible propeller mixers.

Applications

Applicable to aeration tanks and anaerobic tanks in industrial and municipal wastewater treatment plants, it can be used for water circulation in the tank and to create water flow during nitrification, denitrification, and phosphorus removal stages.

The mixed stirring series products use multi-pole motors, adopting a direct connection structure, with low energy consumption and high efficiency; the impeller is precision cast or stamped, with high precision, large thrust, and a beautiful and smooth appearance, compact structure.

The low-speed streamer series products use cycloidal pinwheel reducers, equipped with low power, low speed, and large impeller diameter, covering a wide service area. The impeller is made of polyurethane material and aluminum alloy, with high strength and strong corrosion resistance. In addition to stirring functions, it also has the role of streaming and creating water flow.

The motor winding of the submersible mixer is F-class insulated, with a protection level of IP68. When used in conjunction with the aeration system in wastewater treatment plants, it can greatly reduce system energy consumption and significantly increase oxygenation, effectively preventing sedimentation. According to process requirements, direct-connected submersible mixers can be equipped with flow deflectors.

Applications and Applicable Conditions of Submersible Mixers

The mixed stirring series submersible mixers are suitable for various water treatment processes and industrial processes that require uniform mixing reactions of solid-liquid two-phase or solid-liquid-gas three-phase media.

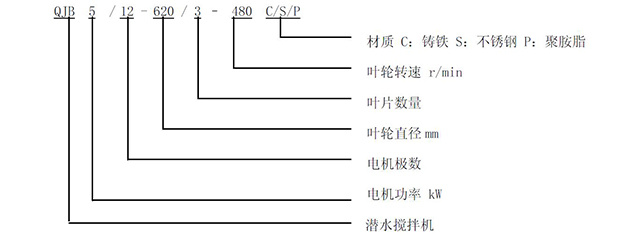

Model Representation Method

Applicable Scope

The QJB multifunctional vortex submersible mixer can operate continuously under the following conditions:

1. The maximum medium temperature does not exceed 40°C;

2. The pH value of the medium is between 5 and 9;

3. The medium density does not exceed 1150kg/m3;

4. Long-term submersible operation, with a general submersion depth not exceeding 20m.

Features

1. Compact structure, small size, lightweight, simple operation and maintenance, convenient and quick installation, and long service life.

2. The impeller is optimized by CFD design, with high efficiency, and the backward-swept blades have a self-cleaning function to prevent debris from entangling and clogging.

3. When used in conjunction with the aeration system, it can significantly reduce energy consumption, increase oxygenation, and effectively prevent sedimentation.

4. Unique cable sealing design eliminates the risk of cable water leakage.

5. The motor winding is F-class insulated, with a protection level of IP68, using maintenance-free imported bearings with one-time lubrication, equipped with oil chamber leakage detection and motor winding overheating protection functions, making the motor's operation safer and more reliable.

6. Two independent mechanical seals, with the friction pair material of the mechanical seal being corrosion-resistant tungsten carbide, and all fasteners made of stainless steel.

Selection Considerations

To ensure optimal results, please provide the following information:

1. Purpose of use;

2. Tank shape;

3. Tank size, including water depth;

4. Medium characteristics, including viscosity, density, temperature, solid content, etc.

The required supporting power of the mixer is determined based on the volume size, pool type dimensions, density, and viscosity of the liquid being stirred. Depending on the specific situation, one or more mixers may be used.

The QJB type multifunctional vortex submersible mixer must be completely submerged in water to operate and cannot work in flammable, explosive environments or environments with highly corrosive liquids!

Main performance parameters of the low-speed flow submersible mixer

Serial Number Type Number Motor Power (kW) Rated Current (A) Blade Speed (r/min) Blade Diameter (mm) Axial Thrust (N) Weight (kg) 1 QJB1.5/4-1100/2-63/B 1.5 3.9 63 1100 680 150 2 QJB2.2/4-1100/2-87/B 2.2 5.3 87 1100 1925 160 3 QJB3/4-1100/2-115/B 3.0 7.2 115 1100 2240 160 4 QJB4/4-1100/2-135/B 4.0 9.2 135 1100 2640 165 5 QJB1.5/4-1400/2-42/B 1.5 3.9 42 1400 650 150 6 QJB2.2/4-1400/2-51/B 2.2 5.3 51 1400 845 160 7 QJB3/4-1400/2-63/B 3.0 7.2 63 1400 1250 160 8 QJB4/4-1400/2-87/B 4.0 9.2 87 1400 1680 172 9 QJB1.5/4-1600/2-34/B 1.5 3.9 34 1600 680 155 10 QJB2.2/4-1600/2-34/B 2.2 5.3 34 1600 910 165 11 QJB3/4-1600/2-42/B 3.0 7.2 42 1600 1548 165 12 QJB4/4-1600/2-42/B 4.0 9.2 42 1600 1810 170 13 QJB1.5/4-1800/2-30/B 1.5 3.9 30 1800 1120 160 14 QJB2.2/4-1800/2-34/B 2.2 5.3 34 1800 1332 170 15 QJB3/4-1800/2-38/B 3.0 7.2 38 1800 1815 170 16 QJB4/4-1800/2-43/B 4.0 9.2 43 1800 2360 175 17 QJB5.5/4-1800/2-48/B 5.5 11.9 48 1800 2820 186 18 QJB1.5/4-2200/2-27/B 1.5 3.9 27 2200 1110 165 19 QJB2.2/4-2200/2-30/B 2.2 5.3 30 2200 1305 170 20 QJB3/4-2200/2-33/B 3.0 7.2 33 2200 1810 170 21 QJB4/4-2200/2-38/B 4.0 9.2 38 2200 2420 175 22 QJB5.5/4-2200/2-43/B 5.5 11.9 43 2200 2760 183 23 QJB1.5/4-2500/2-27/B 1.5 3.9 27 2500 1250 175 24 QJB2.2/4-2500/2-30/B 2.2 5.3 30 2500 1485 180 25 QJB3/4-2500/2-33/B 3.0 7.2 33 2500 1960 180 26 QJB4/4-2500/2-38/B 4.0 9.2 38 2500 2640 185 27 QJB5.5/4-2500/2-43/B 5.5 11.9 43 2500 2920 193 28 QJB7.5/4-2500/2-48/B 7.5 16.5 48 2500 3230 210 Installation System Description

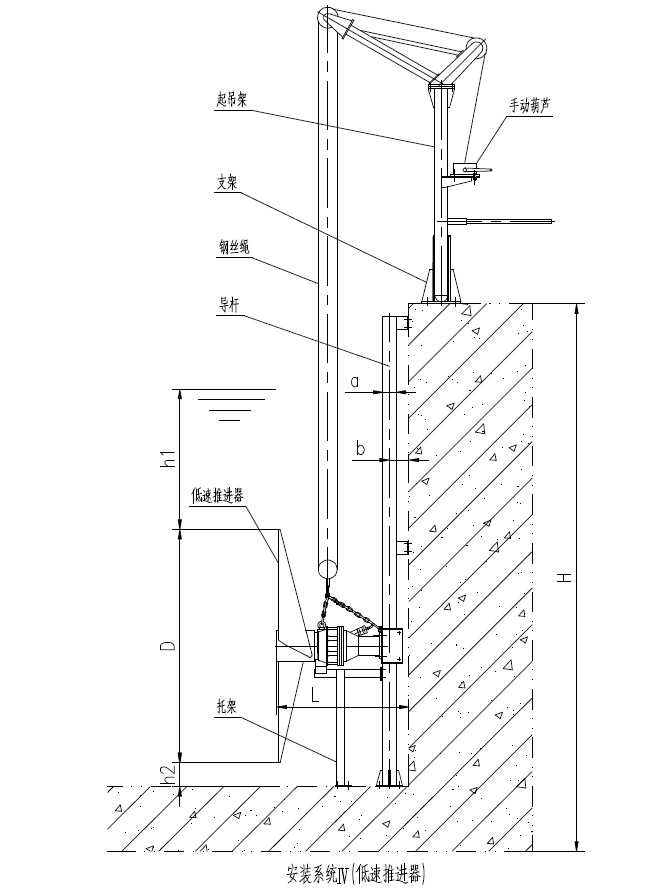

There are various installation techniques available for installing submersible mixers. Below are some commonly used, convenient, and easy installation methods. This specialized installation system can quickly install and dismantle the submersible mixer without the need to drain sewage from the pool. It is also safe and reliable. We can also provide guidance on other installation methods.

The submersible mixer’s immersion depth can be adjusted vertically as needed. The connection between the hanging bracket, support frame, and lower bracket with the pool is fixed by welding to the embedded parts. When placing an order, customers should provide the pool depth H, so that our company can determine the guide rod size and the number of support frames during processing. The material of the installation system is made of stainless steel (or carbon steel). In addition to the hanging bracket, multiple mixers can share one lifting device. To facilitate the installation and lifting of the mixer, a movable door should be opened on the guardrail at the lifting position.

Generally, each specification of the mixer corresponds to a specific type of installation system (see Table 3, Table 4). If users have special needs, other types of installation systems can be provided. The structures of various types of installation systems differ.

Installation Precautions

1. The guide rod should be vertical to the horizontal plane and can be corrected using a plumb line;

2. When lifting the submersible mixer, the impeller end should tilt upwards by 5° relative to the horizontal plane;

3. The lifting center and the lifting center of the submersible mixer should be on the same vertical line;

4. The guide rod and support frame should be firmly welded to the embedded parts at the bottom of the pool.

Installation System IV

Installation System IV mainly consists of a hand hoist, lifting column, hanging bracket, lifting ring chain, hook, guide rod, support frame, etc. The submersible mixer moves up and down along the guide rod through the guide wheel, and the lifting frame is installed on the hanging bracket and can rotate 360° around its positioning axis for easy installation and maintenance. To increase the reliability of the submersible mixer during operation and reduce vibrations during operation, the side of the support frame is directly welded to the guide rod. During welding, it must be ensured that the centerline of the support frame is vertical to the centerline of the guide rod and in the same plane, and a damping block is added between the submersible mixer and the support frame. This installation system is entirely fixed by welding to the embedded parts and does not use expansion bolts for fixing.

Depending on the structure of the pool type, this installation system is divided into two installation methods: wall-mounted and bridge-mounted.

Related products

Product inquiry

Contact Information

No. 192, East Bianzhong Road, Chengqiao Street, Liuhe District, Nanjing